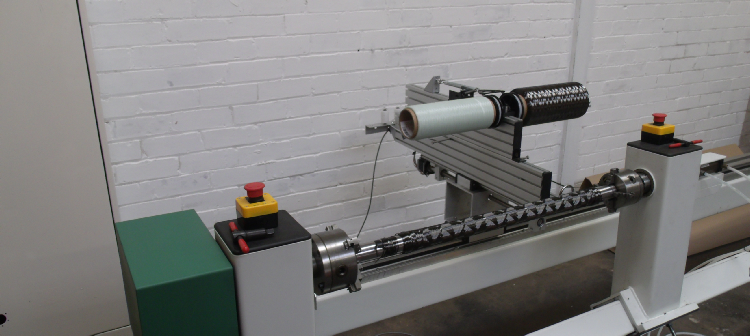

Our production machine is capable of winding up to 500mm diameter mandrels, 3000mm long. This primarily winds Towpreg, but dry and wet winding in carbon, glass and aramid fibres is available.

Machines can be supplied to customer requirements, from benchtop machines of 200mm diameter / 500mm long, upward to 1m diameter and 6m length ( Longer machines are available upon request).

To manufacture tubes with “near zero” axial fibre and Pressure vessels, a minimum of 4 axes are required. All machines are designed to allow retrospective upgrade with additional axes such as plunge, rotating eye, wrist and Lift in addition to the Mandrel rotation and X-axis.

Base machines are designed to run using CADFIL filament winding software, however they can be programmed in

G-code. They are designed to be as compact as possible to minimise floorspace.

Fibres:

Carbon, Glass and Aramid can be would from static creels to the rear of the machine ( 3m space required).

Towpreg can be head-mounted with mechanical tensioners for even tension control throughout the X-axis movement .

Digitally controller electronic tensioners are required if the creel is to the side of the winder.

We use RED Composites towpreg, which provides a controlled resin content and a clean wind, without any resin mixing, no mess and no clean-down. The material has a 3 month outlife without refrigeration.

Diameter: 10- 600mm

Length : 100 - 3000mm

Footprint: 4 x 1.5 m

Creel :

Head mounted 1-4 mechanically tensioned bobbins

Floor mounted (rear) 1–8 Static

Floor mounted (side) 1-4 digitally controlled bobbins